cpk confidence interval

Where ν is calculated based on the method used to estimate σ 2within. Where ν is calculated based on the method used to estimate σ 2within.

Yes since the confidence intervals overlap they are not statistically different Patty agreed.

. The procedure to use the Cpk calculator is as follows. Lower Specification limit LSL 0. The right question to ask is.

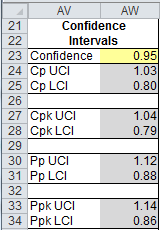

Yes there are formulas for the CIs of Cp and Cpk. The Cpks and sample sizes are entered into the blue cells and the confidence intervals are shown in the gray cells. A process with a Cpk of 20 is considered excellent while one with a Cpk of 133 is considered adequate.

Related

Cp confidence interval bounds. We determined that the Cpks were significantly different if the confidence intervals did not overlap. The 1 -α 100 confidence interval for Cp is calculated as follows.

Now click the button Calculate to get the Cpk. Cpk minUSLμ3σμLSL3σ min16-106 10-46 min 1 1 1. The minimum value of k is 00 and the maximum is 10.

The formula for the calculation of Cpk is Cpk min USL - μ μ - LSL 3σ where USL and LSL are the upper and lower specification limits respectively. Square root of MSSD. ν k - 1.

I found them in the Knowledge Base of Minitab. It requires approximately 100 samples to obtain a confidence interval of 88SD to 116SD. Lest you say that the sample size of 50 gives a confidence interval of 84SD to 125SD recall that the.

How much confidence do I need in the estimate. The spreadsheet can also calculate 95 confidence intervals on Cpks and compare two Cpks to determine if they are statistically different at greater than 95 confidence. This prediction enables us to qualify a new manufacturing process as being fit for use in production.

The addition of k in Cpk quantifies the amount of which a distribution is centered. ν Σ n i - 1 Average moving range and Median moving range. Difference between Cp Cpk and Pp Ppk Potential Process Capability Analysis Cp Cpk.

After a significant amount of research we discovered a technique to calculate the 95 confidence intervals on the Cpk. Madigan asked expectantly. Cp confidence interval bounds.

The confidence interval for the mean narrows quickly and at a sample size of 30 - 50 reaches an acceptable level. I have been doing a lot of reading into Cpk and Ppk recently as we begin to qualify our process for volume production. Square root of MSSD.

ν k Rspan 1. A proper centered process will have Cp Cpk. It evaluates how well the data fits into the specification limits.

ν k - 1. About two-thirds of all end-of-line defects can be traced back to the stencil printing proc. Technical Details This procedure is based on the results of Mathews 2010.

Given the formula to calculate Cpk is. The confidence level for example a 95 confidence level relates to how reliable the estimation procedure is not the degree of certainty that the computed. An estimate for Cpk Cp 1-k.

Then I can say with 95 confidence that the Cpk value is actually. The Cpk 95 confidence interval on the new paste is 095 to 105 however the old paste is 093 to 103 Patty began. A comparison is made by forming the ratio of the spread between the sample mean and.

Yes since the confidence intervals overlap they are not statistically different Patty agreed. Cpk is a process capability index that measures how close a process is running to its specification limits Upper specification LimitUSL and Lower Specification Limit LSL relative to the natural variability of the process. Upper specification limit USL 18.

Go to the Minitab page and make a search you dont need to be a Minitab user. The 1 -α 100 confidence interval for Cp is calculated as follows. I am 95-percent confidant that Cpk is between 119 and 137 according to its.

Note that the statistical comparison of the two cells is shown to the. If a Cpk of 170 is observed we should report I dont know the true Cpk but based upon a random sample of n 30 points I am 95-percent confident that its between 123 and 216 according to its confidence interval On the other hand for the same data set and n 500 points I can say. The Confidence Interval of the Cpk on the New Paste is 095 to 105.

So even I can sense that they arent different Mike commented. I have seen in many instances a mention of confidence intervals on Cpk based upon the sample size. Finally the process performance will be displayed in the output field.

In stencil printing the basic foundation is transfer efficiency. In statistics a confidence interval is a range of values that is determined through the use of observed data calculated at a desired confidence level that may contain the true value of the parameter being studied. ν Σ n i - 1 Average moving range and Median moving range.

You will see this type of confidence interval when you run a single Cpk analysis to help you understand the uncertainty in the results. If a Cpk of 170 is observed we should report I dont know the true Cpk but based upon a random sample of n 30 points I am 95 confident that its between 123 and 216 according to its confidence interval On the other hand for the same data set and n 500 points I can say. So even I can sense that they arent different Mike commented.

A perfectly cantered process where the mean is the same as the midpoint will have a k value of 0. Statistical explanation when curve stretches from 3 to -3 it is believe to occupy 9973 and here the machine is producing 9973 good parts. Not so the confidence interval of the standard deviation.

ν k Rspan 1. A 1001 α confidence interval for Cpk is given by 1 𝑛𝑛 1 9𝐶𝐶𝐶𝐶𝐶𝐶 2 1 2 1 𝑛𝑛 1 9𝐶𝐶𝐶𝐶𝐶𝐶 2 1 2 where 𝐶𝐶𝐶𝐶𝐶𝐶 is the estimated value of Cpk n is the sample size and 𝑧𝑧 is the specific value of the standard One-sided limits may be obtained by replacing 𝛼𝛼2 by 𝛼𝛼. A process capability study uses data from a sample to PREDICT the ability of a manufacturing process to produce parts conforming to specifications.

Enter the lower limit upper limit the mean and standard deviation in the input fields. The Cpk 95 confidence interval on the new paste is 095 to 105 however the old paste is 093 to 103 Patty began. This confidence interval implies that the true Cpk value lies between 092 and 142 again a fairly large range.

This paper will discuss this new work as well as an Excel spreadsheet developed to calculate the Cpks and their confidence intervals. To take the data used in the example the sample size is 120 and the calculated Cpk is 119.

Confidence Intervals Cp Cpk Minitab

Process Capability Vii Confidence Limits

Cpk Confidence Intervals Impact Of Sample Size Qi Macros

Chapter 7 Process And Measurement System Capability Analysis

Cpk Confidence Intervals Impact Of Sample Size Qi Macros

Calculating Confidence Intervals On Cpks Dr Ron Lasky Indium Corporation Blogs Solder Reliability

Process Capability And Variation Bpi Consulting

Process Capability Metrics Z Score Defects Ppm

Chapter 7 Process And Measurement System Capability Analysis

Cpk Confidence Level Jmp User Community

Cpk Confidence Intervals Impact Of Sample Size Qi Macros

Cpk Confidence Intervals Impact Of Sample Size Qi Macros

Process And Measurement System Capability Analysis Ppt Download

Process Capability And Confidence Intervals

Process Capability How Many Data Quality Digest

Calculating Confidence Intervals Of Cpk In Stencil Printing Youtube

Process Stability Performance And Capability What Is The Difference

0 Response to "cpk confidence interval"

Post a Comment